Hitech Enterprises, established in 2017 at Sonipat, Haryana. We are one of the leading manufacturers and suppliers in Rubber Testing Equipment. In research on compound development and production management in the rubber industry, the influence of compound morphology on vulcanization properties is important. During compound development, the composition of the ingredients may be varied until the desired curing properties are achieved. However, computerized rheometers with microprocessor temperature control are important equipment. The invention of new rubber polymers and chemicals has put mixers in a difficult position for selection and use.

In the rubber industry a rheometer is the only piece of equipment that helps processors select the right material and the right dosage for resale of their final product. The rheometer not only indicates the vulcanization properties of the compound, but also shows the physical properties of the vulcanization and processing properties. Actually, rheometers have several advantages: Over the years, we have protected many homes, high end industries, educational institutions, 5 star hotels and offices across India. We guarantee that your personal attention is always unparalleled.

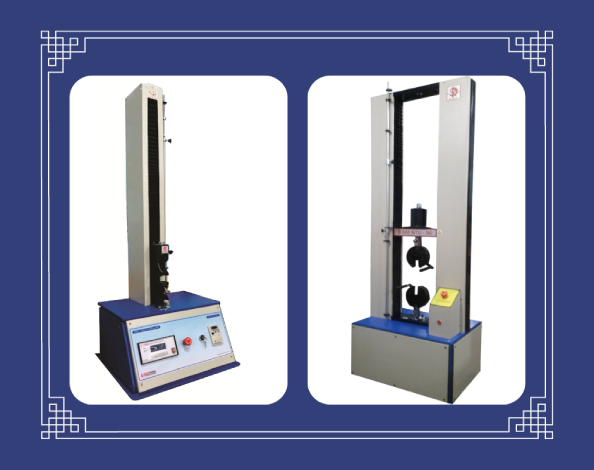

Hitech Enterprises is continuously devoted to research and development of new products, and has obtained lots of technical patents year after year. Currently we mainly provide Moving Die (Foam Pressure) Rheometer, Mooney Viscometer , Oscillating Disc Rheometer, Tensile Testing Machine, Cutting Dies for Tensile, Universal Testing Machine Computerized, Tensile Testing Machine Digital, Lab Mixing Mill, Dumbell Cutting Die with Press, Aging Oven, Din Abrasion Tester, Muffle Furnace , Sp. Gravity Meter Digital, etc.

The Rheometer gives us the true picture regarding the processing behavior of the rubber compound. By having the complete picture i.e. Viscosity, Scorch time, Optimum cure time of rubber compounds, the compounds are stored, processed and used accordingly. Unused compounds left for longer periods will tend to cure rendering it unsuitable for future use. Such mixes can be tested easily on the Rheometer and decision can be taken regarding their utility. The ability of a Rheometer to detect minor changes in the composition of Rubber Compound has made it a widely accepted Production Control Test Equipment.

In order to produce consistent quality of Rubber products, it is of vital importance that compounded rubber is of consistent quality. As the compound is mixed in batches, batch to batch variation, if any, needs attention in controlling quality of each batch. If randomly selected batches are subjected to Rheometeric analysis, one could in a large sample size, workout upper and lower control limits, range, mean and standard deviation, with reference to Rheological parameteres. Each batch on testing can be classified on Pass/Fail criteria depending upon the quality control limits. Based on this, the internationally acceptable control called "Statistical Quality Control" (SQC) can be designed. Computerized data ana-lysis system of Rheometer.